Polish grinding Yankee cylinders

Polish grinds are periodically necessary for Yankee cylinder maintenance to remove chatter marks, corrosion and scoring, caused by wear or damage during operation.

This polishing technique is an economical way to quickly restore the optimal surface condition.

Machine down-time / required time for polish grinds:

E.g. Yankee Ø 4572 x 3300 mm (incl. installation and disassembly of the machine): 14 h

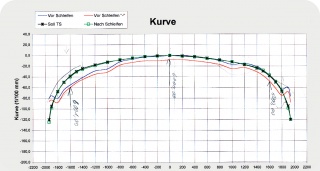

If required the cylinder geometry can be optimized as well.

Advantages of the compact design of this grinder YP (YankeePolisher):

- easy and fast installation directly on the existing doctor blade holder

- short machine down-time required, polish grinds can be performed during scheduled machine down-time (polishing including installation and disassembly time 12 - 27 h)

- high removal rate

- modular set-up - no crane required

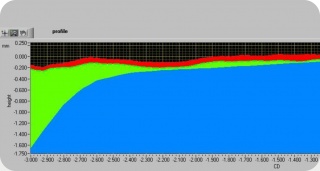

During the grind and polish the required surface roughness will be accurately achieved and verified by measurements. The actual result is documented in the final report. ►►

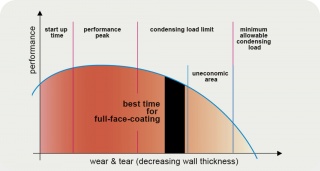

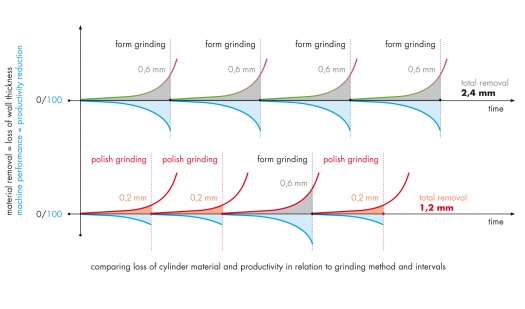

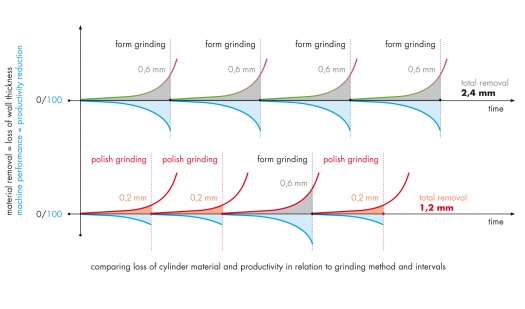

Optimal grind intervals for Yankee reconditioning: a matter of right timing

Choosing the right time to restore the Yankee surface maximizes machine efficiency and reliability. Optimal surface conditions are required for high production efficiency and product quality, but routine polishes will also minimize material removal and thus cylinder shell thickness reduction. Deterioration of the surface through operational wear, corrosion and/or chatter-marking is exponentially progressive. Consequently, delaying the scheduled date for a polish grind for too long (for instance to match a scheduled general maintenance down) will result in excessive shell material removal required. Due to the severity of the then developed surface defects, a profile grind becomes the only option and normally requires 4 to 8 times more material removal compared to a timely scheduled polish grind.

With reducing shell thickness the cylinder casting will become increasingly more porous and consequently less stress resistant in operation. In such a case it is worth to consider implementing a Full-Face-Coating in your Maintenance Plan, in order to prolong the cylinder life as much as possible.

Machine down-time and maintenance cost for a polish grind prove to be low, both in direct comparison as well as in long-term calculation. With the right timing of the grind intervals the life of the cylinder can be extended considerably.

Indicators for a polish grind:

- reduced doctor blade life

- chatter marks in cylinder surface

- holes in tissue

- tearing and sheet breaks

- increased usage of coating chemicals or irregular coating build-up

- reduced productivity