TM: Analysis/Measurements

Condition analysis of Yankee cylinders:

Generally:

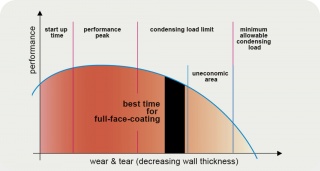

A reliable state determination is an important prerequisite for optimal investment planning and coordination of maintenance activities.

The optimal sequence of the individual steps in the analysis is:

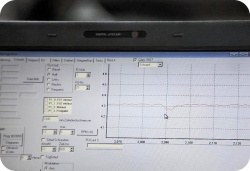

- analysis of bearings and drive (vibration measurements ...)

- examination of cylinder geometry (crown, concentricity ...)

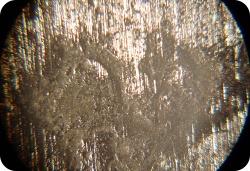

- examination of cylinder surface (chatter marks, corosion, edge wear ...)

- functional analysis and optimization potentials (doctor systems, condensate removal systems ...)

Analysis of the surface:

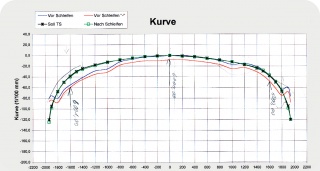

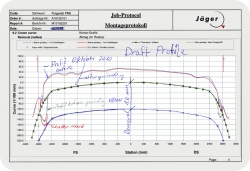

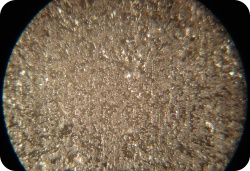

With the help of visual examinations, measurements of roughness, shell thickness and thickness of coating layers , prints, microscopic images and other diagnostic techniques, the state of the cylinder surface is assessed. The recorded results of these studies provide reliable information, based on which restoration measures can be recommended.

Details, photographed with magnifying glass, provide information about surface finish

A careful analysis of the condition of individual cylinder surfaces documents exactly the actual state with the help of meaningful measurement reports. Their expert evaluation is the basis and prerequisite for recommendations, effective action planning and the optimal investment planning in terms of maintenance and repair. ►►