TM: Full-Face-Coatings ...

Thermal sprayed carbide coatings

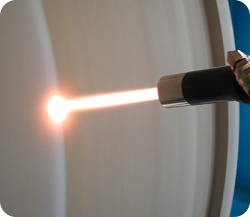

The method:

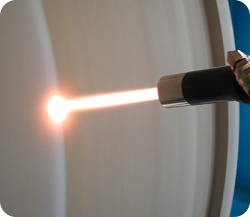

Metal powder or wire is sprayed onto the cylinder surface by injecting it into a burner flame, heating it and accellerating it (up to a speed of 1000m/sec = 3.600 km/h). In this way the metal particles are connecting firmly with the cylinder´s surface at a molecular level.

By the goal-oriented combination of the factors

- selection of metal alloy and particle size

- thermal energy

- kinetic energy

the required characteristics of the coated surface will be achieved.

Depending on the production use of the cylinder it´s surface characteristics can be significantly improved.

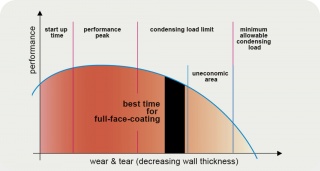

Moreover, of course, the applied carbide coating has a much higher resistance to wear and damage than the cast iron of the cylinder shell has. Thus, the maintenance intervals are extended and the wall thickness of the cast substance is maintained, because the cylinder has to be ground less often and with less loss of material. This leads to a relatively rapid return on investment for the coating. ►►

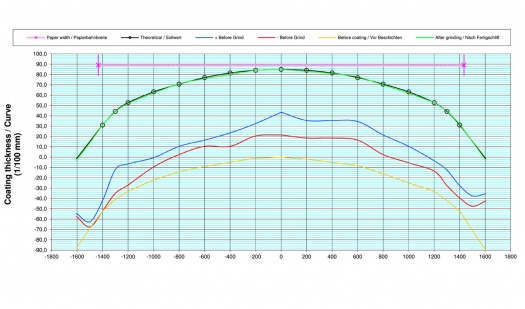

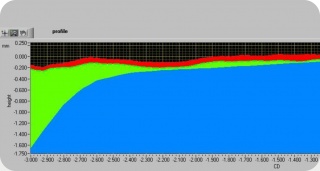

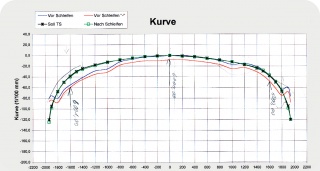

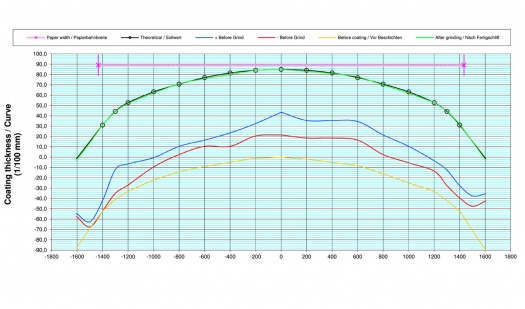

Changes of cylinder contour by grinds / coating

The graphs below show up the various changes of the yankee contour caused by grinds and coating with a YC 35.

Targeted selection of the best method ...

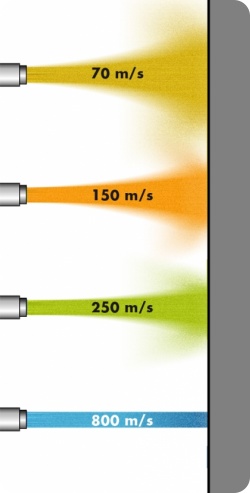

The use of different injection techniques in the coating of cylinders with hard metal layers produces different results.

After years of experience and as a result of an extensive series of experiments in most cases we recommend to our customers the so-called high-speed coating method (HVOF).

This relatively complicated process reaches by far the smoothest, thinnest and most uniform layer application as a result of the coating.

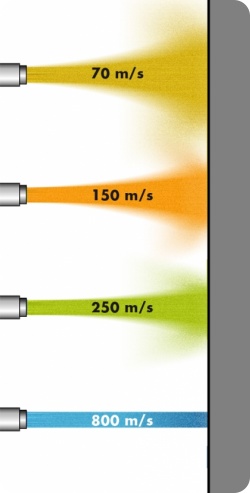

flame spraying

up to about 70 m/s, dispersion strong,

spraying distance about 150 mm

light arc spraying

up to about 150 m/s, dispersion strong,

spraying distance about 120 mm

plasma spraying

up to about 250 m / s, dispersion medium,

spraying distance about 100 mm

high speed spraying (HVOF)

up to about 800 m/s, dispersion low,

spraying distance about 350 mm

General advantages of full-face-coating:

General advantages of full-face-coating:

- uniform, smooth surface

- improved resistance to wear and tear

- extending the grinding intervals twice

- sealing of pores and plugs

- improving the chemical coating result by the more even surface roughness.

- longer life cycle for doctor blades

- higher and more constant productivity

- maintaining the cylinder for further 4–8 years

Advantages of traction coatings on support rolls:

- stopping traction problems like wrinkling, paper damages and tears

- surface roughness uniform and adequate for the respective product