PM: Contour Grinding

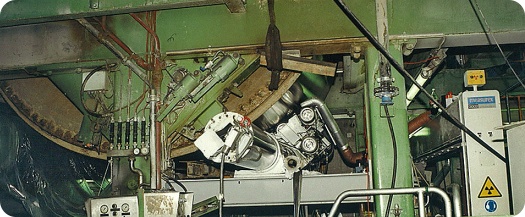

Restoring cylinder contour

in tangential grinding method

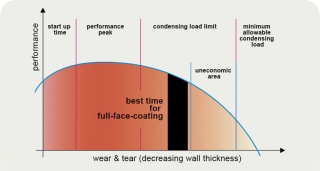

In addition to the cleaning and polishing grinds to optimize the surface quality and roughness, the profile- or contour grinding is one of the major restoration measures at Yankee dryers. Both grinding operations can be performed independently or planned as two different steps of the restoration process. They are often used in combination with a full-face-coating, a spot- or edge repair for a long term preservation of the optimal cylinder shape, the contour grinding work provides.

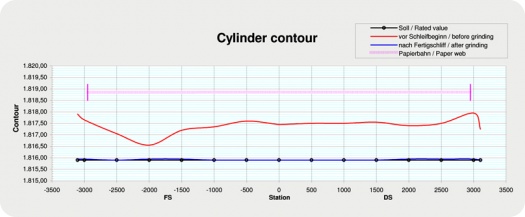

Precise adherence to the grinding program based on the previously calculated reference values for the cylinder profile not only guarantee the correct cylinder shape, but also helps to avoid unnecessary loss of wall thickness and cylinder substance.