Vibration Issues ...

Elimination of vibration problems

in a paper machine

Problem:

Decreasing product quality and high frequency of paper tear caused by strong longitudinal variations in the drying section of a paper machine in Austria.

Work performed:

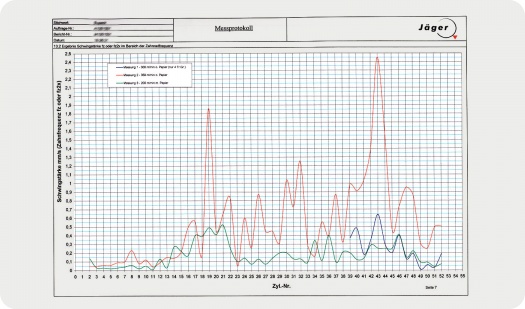

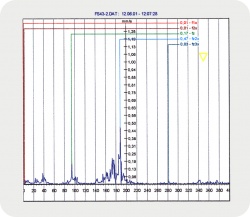

- Analysis of vibrations in the dryer section.

- Assessment of the measurement and definition of measures.

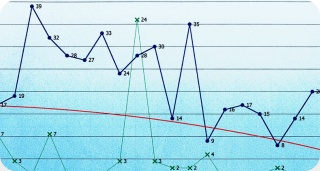

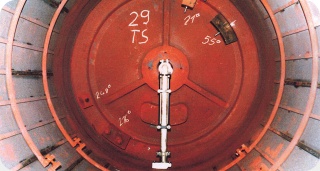

- Then, the balancing of drying cylinders in installed condition.

Special features:

Special features:

Conducted vibration measurement yielded a specific statement about the causes (drying cylinders, guide rollers, drive sprockets).

Only the problematic cylinders were balanced and only the affected gears were replaced.

As a result, the cost has been reduced to the minimum, unnecessary requirement of time and costs has been avoided.

Result:

The problems have completely been eliminated, the drying section today runs without any disturbing vibrations.